Scientists at Oak Ridge National Laboratory in Tennessee have developed wireless charging technology that they say could fill up a typical electric car today in under an hour. This represents a six-fold improvement over a similar wireless charging system they announced in 2016. That plugless EV charging technology, they report, is now being modified for commercial applications including delivery trucks.

And the team isn’t done, says Burak Ozpineci, leader of Oak Ridge’s Power Electronics and Electric Machinery group. They are, he says, working toward the larger goal set by the U.S. Department of Energy (DoE) to build a portfolio of rapid, safe, and easy electric vehicle charging systems—which would, as the DoE’s 2016 mandate put it, “accelerate electric vehicle adoption in the United States.”

The idea is to increase the power throughput of their present system by another factor of three—bringing the total charge time for an empty electric vehicle (EV) battery to under 15 minutes. All without needing to plug anything in to the car or really do anything other than drive the EV over a wireless charging plate embedded in the concrete.

The Energy Department’s mandate, Ozpineci says, didn’t specify whether such systems should be wired or wireless. But he adds, “Our expertise is in the wireless side. So we said, we’ll do the wireless part.”

While artists' concepts today depict filling station-like EV pumps that dispense a torrent of electrons like petroleum 2.0, wireless EV charging potentially represents more than just a new source of automotive fuel. Like the wireless Internet revolution of 20 to 30 years ago, wireless EV power could change more than just a car’s power source. Some futurists have seen wireless power playing a role in the rise of the "smart city" and the demise of the gas station.

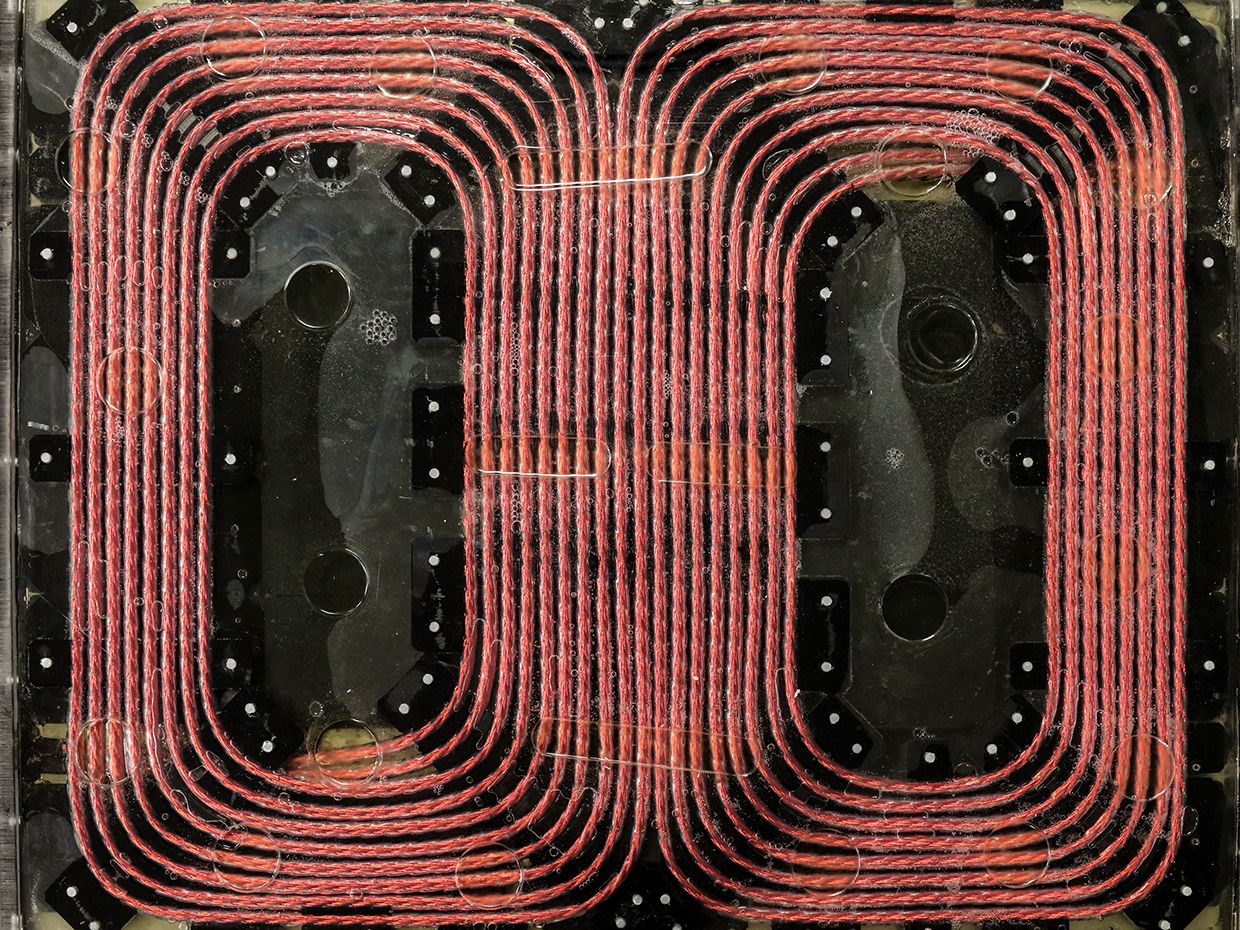

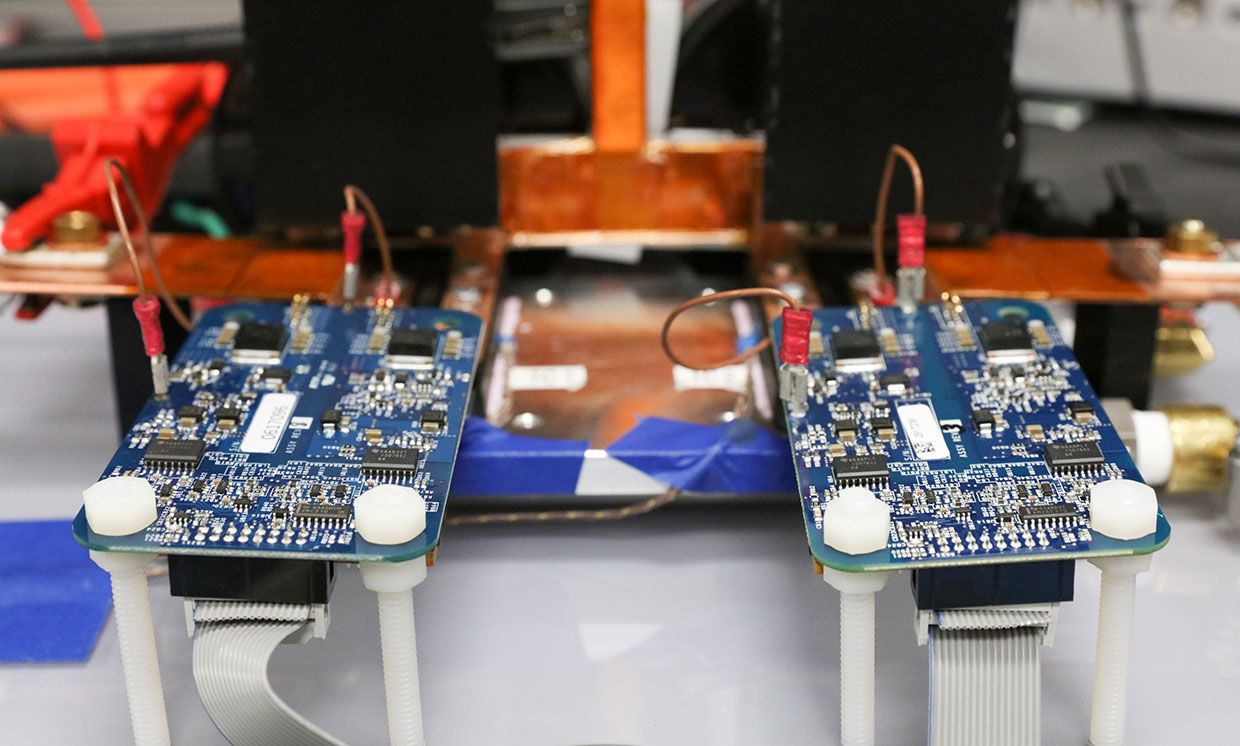

Ozpineci says two key elements of their 97 percent efficiency, 120-kilowatt wireless charging technology concern the material they made it from and the coil that transmits and receives the electric power. They presented details, which will soon be published on the IEEE Xplore database, at IEEE’s Energy Conversion Congress and Exposition in September.

To beam wireless power from a floor unit to a power receiver unit in an EV, separated by some six inches of open air, means rapidly oscillating the electric and magnetic fields in the coil, inducing similar behavior in the receiving coil in the EV. Practically speaking, Ozpineci says, that means pumping out 120 kilowatts through oscillating currents at some 22,000 cycles per second (i.e. 22 kHz).

“The problem is typically we have silicon devices, and when we go to higher power levels, you cannot run them at higher switching frequencies,” he says. “At 10 kilowatts, you can switch at 20 kilohertz. But when you go up to 100 kilowatts and beyond, you have to reduce your switching frequency—because of thermal issues, because of the device response, because of a number of things.”

But transferring higher power levels at high efficiency demands higher switching frequencies. So this effectively means both swapping out silicon for more robust (and more expensive) silicon carbide and strengthening the coils on both sending and receiving ends of the power exchange.

Tesla’s Model 3 also uses silicon carbide electronics, Ozpineci says. So the Oak Ridge technology’s reliance on the material is not unprecedented in EV systems. On the other hand, they admit their 100-pound coil needs some refining and optimizing before it could ever be scaled out into a production-quality design.

Then, they must produce three times more power from their design to reach the Energy Department’s 350 to 400 kilowatt target. Ozpineci says it’s a work in progress, but he suspects there will have to be multiple power modules in any 350-kW or more wireless supercharger.

“We’re able to use single power modules,” he says of the current 120-kW unit. “We’re at the limit or almost at the limit of these power modules. When you go to anything beyond that, we’ll have to either parallel these modules, or we have to have two inverters in parallel. And when you do that, you have a lot more challenges of running these things in sync.”

Ozpineci says his group is also working on a feasibility study of so-called dynamic EV charging—in which embedded wires in a road surface can charge a car as it’s driving down that road.

“Many groups in the world have looked at it, but most have looked at it for lower power,” he says. “Like 20 kilowatts. But we’re not limiting ourselves to 20 kilowatts. Do we need 100 kilowatts, do we need 120 kilowatts, do we need higher? Whatever results we get out of this, DoE might fund a demonstration.”

0 Comments